Optimizing machine vision lighting for food and beverage inspection.

Figure 1. Brown rice illuminated by SWIR light at a wavelength of 1550nm shows strong absorption.

Inspection of food, beverages and related packaging requires the ability to process images for a variety of parameters such as size, shape, color, flaws and finish. To achieve this, optimizing the brightness, uniformity and geometry of the lighting is critical to achieving images with good contrast and reasonable signal/noise. Additionally, the diverse light absorption properties of organic and inorganic materials can make it difficult to select the appropriate wavelength for these applications. To make the best lighting choices, engineers and integrators must understand the fundamentals of lighting and the latest technologies to ensure the best results.

In terms of wavelength, the visible (RGB), near infrared (NIR) and shortwave infrared (SWIR) spectrums can all play a role in these inspections. Infrared wavelengths are often very effective in detecting defects and contamination by foreign bodies, molds, diseases and pests in harvested products such as fruits, vegetables, rice, corn, nuts, soybeans and coffee.

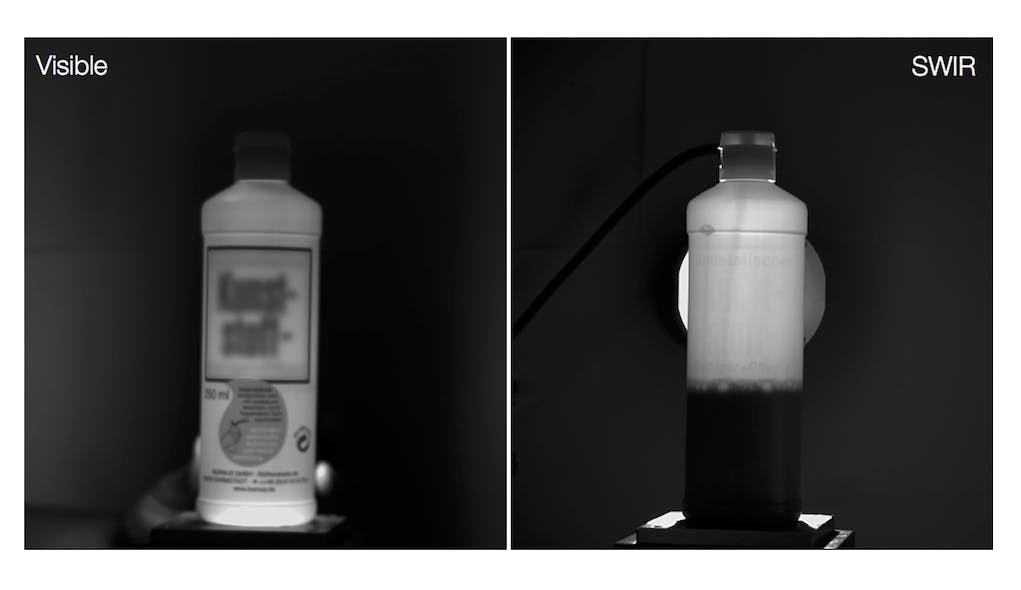

Figure 2. SWIR light shining on the plastic bottle label makes it transparent, allowing for easy measurement of the water level of the liquid based on water.

Figure 3. The internal bruise on the apple cannot be detected using RGB light (left). However, SWIR light makes it very easy to detect the bruise (right).

Optimal wavelengths often exist for the color of each sample. For example, brown rice, when illuminated at a SWIR wavelength of 1550 nm, exhibits strong absorption compared to a red rice sample (Figure 1). SWIR light effectively measures the degree of gray filling in glass and clear plastic bottles that absorb water, as water-based liquids appear dark in SWIR light. (Figure 2). Subsurface defects such as bruises on fruit, which are difficult to detect with white light, are readily visible under infrared light (Figure 3).

Ultraviolet (UV), red, green, and blue light can also often reveal more information than white light. LEDs provide light spanning all of these wavelengths and therefore serve a variety of different types of inspection. If a product sample contains multiple types of defects, each of which is most easily identified by a different wavelength than the others, it may be useful to use multiple LEDs tuned to different wavelengths simultaneously.

Broadband LED hyperspectral lamps are more suitable for thermally sensitive product inspection than the traditional halogen lamps used for hyperspectral imaging. A large portion of the energy produced by traditional illuminators is outside the wavelengths of interest, creating excess heat. Temperatures can exceed 100°C, depending on the specific halogen type, so active or inactive cooling is often required. Broadband LEDs are available that operate cool and ensure that the light does not melt the product or accelerate deterioration.

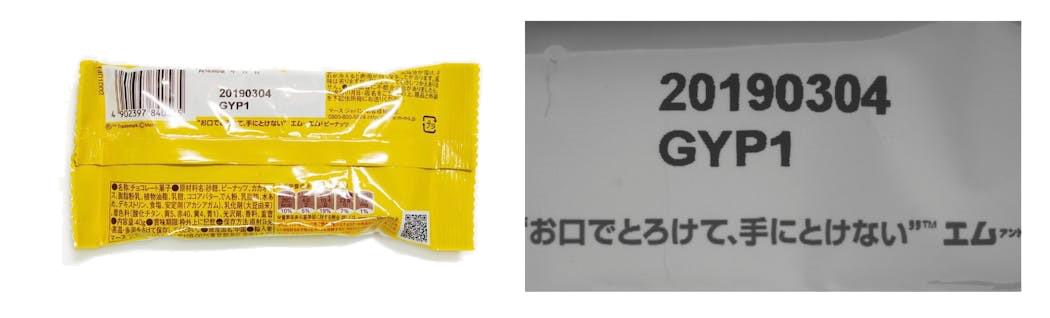

Food and beverage packaging can be made up of a variety of materials, types and sizes, each of which may have an optimal light wavelength for the inspection application. For example, the reflection from the packaging material in Figure 4 can interfere with the ability of the vision system to read the printed text correctly. The use of red light makes the yellow packaging lighter in the output image so that the text on both the white and yellow portions of the packaging has high contrast against the background.

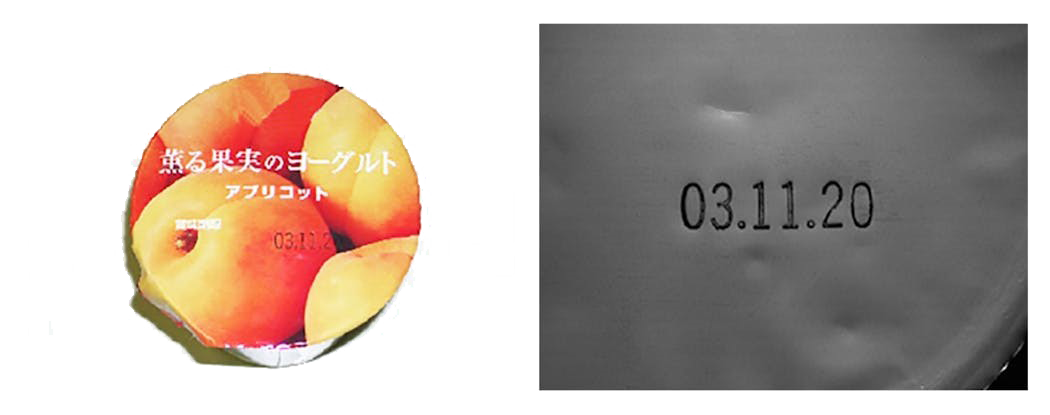

Infrared imaging serves food packaging inspection applications by making it easier to read codes and expiration dates. For example, Figure 5 shows a lid with a difficult-to-read expiration date. Light at 940 nm is absorbed by the ink in the printed image and reflected by the ink in the expiration date, creating contrast that makes the expiration date easily visible and visible. Additionally, the light also reveals defects such as tears and holes on the actual surface of the packaging.

Longer wavelengths, or shortwave infrared light, are often useful in food and beverage inspections, especially those involving water or moisture content. A common problem with SWIR LEDs is their significantly lower intensity compared to conventional visible LEDs.

Recent advances in high optical power (HOP) SWIR light sources, based on a proprietary material developed by CCS group member EFFILUX, emit SWIR light that is up to 10 times more intense than other similar LED sources, providing significantly improved contrast for high-speed inspection applications. Lights using HOP technology can produce highly focused SWIR light beams as well as large-area uniform SWIR light and specific projection patterns.

These high optical power lights, compatible with most of EFFILUX’s standard lighting configurations, provide a range of popular lighting solutions commonly used in SWIR camera applications.

Hyperspectral imaging can also help inspect heat-sealed packaging to check for any contaminants trapped in the seal itself, which could compromise product integrity. Infrared light penetrates the packaging at the seal and the specific wavelength of light at which the contaminant appears allows its chemical composition to be analyzed. Subsequent analysis allows the source of contamination to be identified and eliminated.

Figure 4. The red LED light shining from above eliminates glare from the reflected light on the candy packaging and improves contrast when reading the production date code.

Once the appropriate light wavelength has been determined, the light source shape, or form factor, must also be selected. LEDs come in ring, convex, coaxial, tube, bar, and line shapes. In addition to demonstrating the value of red LEDs in this application, Figure 4 also shows the benefits of using a flat convex light source that produces a uniform, diffuse light pattern that eliminates reflections. The flat convex light in this example, only 10 mm thick, can fit into a confined inspection space.

Figure 5. The infrared LED makes the printed text on the plastic lid invisible, making the production date code easier to read.

Ring lights can illuminate objects from above, with the camera looking through the center of the ring. This technique illuminates diffuse, non-reflective objects, as in the example in Figure 5, using a ring light with infrared LEDs. Low-angle ring lights, with LEDs mounted on a flexible circuit board at a steep angle in the ring, allow the light to be mounted closer to the object being inspected. This creates a dark backlight that creates surface features. The camera only receives the light scattered by the imperfections.

As important as the shape of the light, how the LED performs in the sometimes clean or humid operating requirements of food and beverage inspection can be an important factor in selection. The IP69K vapor-proof housing can withstand high pressure and high temperature cleaning requirements. IP65 and IP67 housings support other cleaning systems.

Consistency of light quality is especially important in food and beverage inspection, where variations in lighting conditions can lead to inaccurate results. Smart lighting solutions, such as CCS’ Fastus system, provide advanced control functionality to account for the degradation of brightness over time due to the natural aging of LEDs, or changes in external factors such as temperature or ambient light conditions. Additionally, smart lighting solutions can log and record data on equipment maintenance and light quality consistency, which can meet FDA data tracking requirements.”