Modern robot technology - Easy maintenance, increasing cobot life

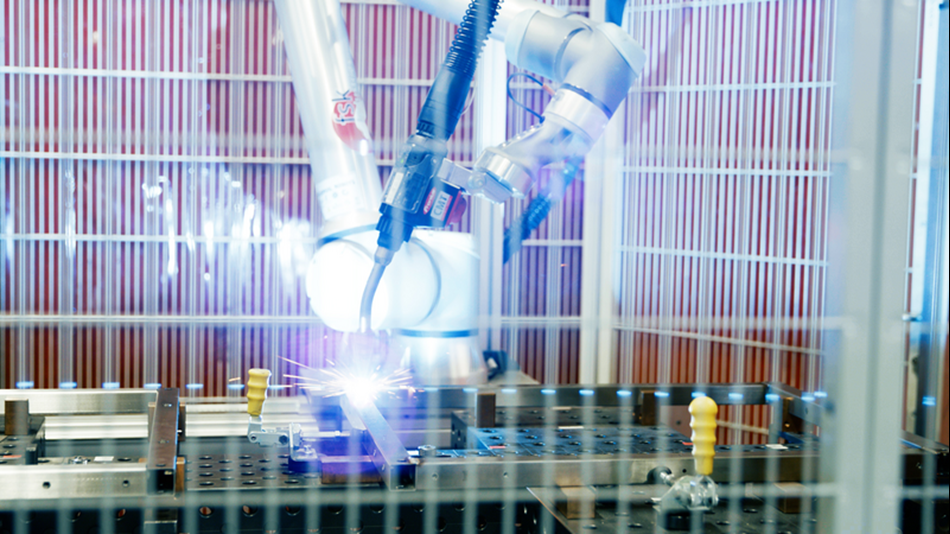

Modern robots serving automated industrial production such as collaborative robots (cobots) today are not only increasingly improved in their ability to perform tasks, deploy or assemble, but their lifespan is also increased and maintenance and servicing are also more convenient and easier.

Increased lifespan helps businesses optimize costs and maintenance and servicing is easy and quick, helping to reduce a large part of downtime for businesses.

By performing continuous tasks for a long time as well as working in dusty environments, collaborative robots still maintain their durability. Let's find out what makes cobots so durable.

MODERN ROBOT TECHNOLOGY IMPROVES THE LIFESPAN OF COLLABORATIVE ROBOTS

To undertake tasks in harsh environments such as dust, heat or humidity, modern robots such as UR collaborative robots must ensure quality and have extremely good durability.

To undertake tasks in harsh environments, modern robots such as UR collaborative robots must ensure high quality and extreme durability.

Universal Robots’ cobots feature a “no-gap” design with their internal electronic components sealed in a metal housing. These state-of-the-art cobots are IP54-rated, which means they can keep out some dust and can withstand water sprays or sprays from any direction.

At Aircaft Tooling Inc. (ATI), cobots are used in the harsh and dangerous task of plasma spraying parts. To do this, the cobots are placed in extremely hot and dusty spray booths. However, the harsh conditions did not affect the cobots. Juan Puente, ATI’s thermal spray supervisor, was surprised because he did not expect cobots to be able to withstand this environment. “Some of these powder coatings are tungsten carbide, a hard metal coating,” he said. “If it got into the bearings of the robot, we were afraid it would destroy them.” After opening up the UR10 robot, ATI found that the bearings were still intact. “There were no paint particles in there after three years of operation,” Puente said.

The cobot’s lifespan was up to 35,000 hours under test conditions where the cobot ran at full capacity with the highest internal load and fastest speed. This means that the modern robot will last much longer under normal production conditions.

Modern robots like UR collaborative robots can operate continuously at peak productivity for 35,000 hours

Many real-world examples show that collaborative robots are incredibly durable over time. For example, at gear manufacturing company BJ Gear, the UR collaborative robot used at the company can still work well 14 hours a day. Since its introduction six years ago, the company has only had two joint replacements over the years. Lars Bak, plant manager at BJ Gear, said the factory has not experienced any downtime since adopting collaborative robots, despite the fact that they have been through the highest work cycles.

MODERN COLLABORATIVE ROBOT - MAINTENANCE AND SERVICE HAS NEVER BEEN EASIER

In fact, collaborative robots can operate for years without any problems, and without the need for maintenance. “All we do is dust off the robot arms and let them keep working,” said Puente, a thermal spray supervisor at ATI.

Modern robotic arms can operate for years without any problems.

However, if maintenance of the robot is required, this is also extremely easy and simple. Thanks to the safety, without the need for protective barriers (after risk assessment), the operator can easily access and perform disassembly, maintenance or replacement of parts on the robot.

Disassembling and replacing collaborative robots is also extremely simple and easy without affecting other parts thanks to the benefits of modular design

In addition, with a rounded, compact design, modern collaborative robots do not pose any danger when disassembling or replacing. Disassembling and replacing is also extremely simple and easy without affecting other parts thanks to the benefits of modular design. “With the modular design of the UR robot, we can install the parts ourselves without depending on the integrators." - According to Quitzau, Senior Technical Director at medical device manufacturer Tegra Medical - where UR collaborative robot arms are deployed to care for medical device manufacturing machines.

The robot can easily change joints when necessary and this only takes about 30 minutes. Replacement parts can be easily found at distributors worldwide.

SUMMARY

Modern robots such as collaborative robots with their long life, durability and low maintenance requirements help manufacturers quickly achieve the desired ROI and minimize downtime.

Article source: universal-robots.com