Metal detectors in the Food industry

Why use metal detectors in food?

The main purpose is to protect consumers. Despite all precautions, the possibility of metal contamination in products cannot be completely ruled out. Metal particles can enter the product during the manufacturing process or are already present in raw materials, causing serious harm to consumers, with significant consequences for the manufacturing company such as compensation claims, product recalls. The greater and longer-term damage is the negative brand image and loss of consumer confidence caused by unclean food products.

Metal detectors for food provide effective protection against ferrous and non-ferrous metals (aluminum, stainless steel, ...). They can be installed at every step of the production process and can be used for a variety of applications, such as checking bakery products, meat, sausages, fruits, vegetables, milk, spices, sugar, etc.

In addition to protecting consumers, metal detectors are also used to protect machinery. Even the smallest metal particle can cause damage to machinery. The result is repair costs, production downtime and lost revenue.

Where are metal detectors installed in the food production process?

When used for machine protection, metal detectors are installed directly in front of the machine to be protected. As in most cases in the food industry, if the goal is to protect consumers, there are several useful inspection points. Raw material inspection has the advantage that metal particles are removed before they break into smaller, more difficult-to-detect pieces. Inspections at critical control points (HACCP) during production should be carried out to detect machinery failures (such as broken blades) in time.

Therefore, food products at the final stage after packaging are re-inspected with a metal detector (or X-ray system) to completely eliminate contamination.

For optimal product protection, raw materials, some critical control points and final inspection of the finished product should be carried out.

How does a metal detector work?

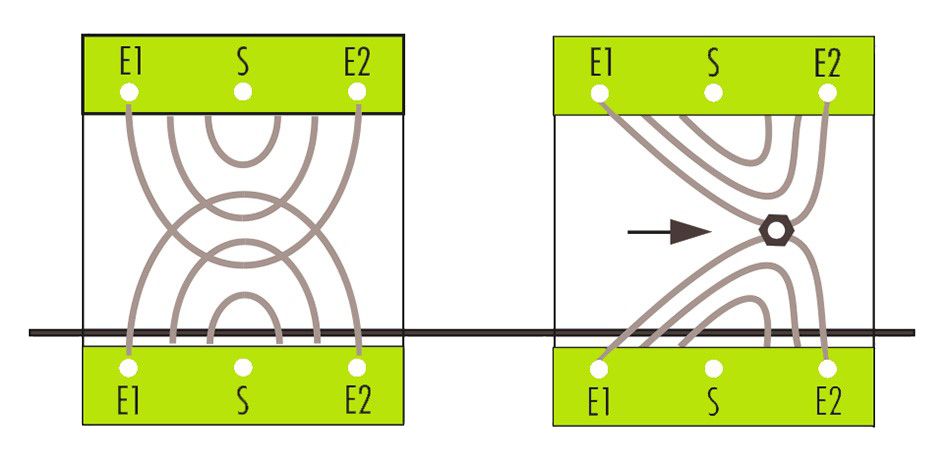

Basically, there are several types of metal detectors that operate with different detection methods. In the food industry, metal detectors are often used with the transmit-receive method.

Such metal detectors are equipped with a transmitter coil and two receiver coils. The transmitter coil generates a constant electromagnetic field. When a metal particle passes through the detector, it interferes with the electromagnetic field, causing a signal to be detected by the receiver coils. The electronics in the metal detector analyze this signal, evaluate it, and signal metal contamination. As a rule, metal detectors in the food industry are equipped with an automatic reject device that directly separates contaminated products from the production line.