Identify the critical control points in the food production process

Identifying Critical Control Points

All food intended for human consumption must be absolutely pure and clean. This is one of the most important requirements in the food industry. A decisive criterion here is that the product leaving the factory is free from contamination with metals and other contaminants. Testing products for metal contamination has become an integral part of the food production process, an inherent part of HACCP (Hazard Analysis and Critical Control Points) and a prerequisite for successful IFS certification.

What is a Critical Control Point?

In a comprehensive and systematic HACCP concept, it is not enough to simply test the final product for contamination, as this means that there is still a risk of contamination in the raw material, which may be broken down into very small pieces during processing. Therefore, to ensure optimal food safety, testing must be carried out at various points in the production process. The HACCP concept requires that all control points associated with unacceptable health risks to consumers must be identified. These points in the production process are called CCPs (Critical Control Points).

In order to identify appropriate CCPs and to achieve a safe HACCP concept, potential hazards in the production process must first be identified by hazard analysis.

Hazard analysis

In hazard analysis, all possible physical, chemical and biological hazards must be identified. For example, physical hazards include contamination of the product with metal, glass fragments, bones, etc. A risk assessment must also be carried out, analyzing the probability of contamination on the one hand and the impact of such contamination on the other.

In summary, the following questions must be answered in a hazard analysis:

What types of contamination can occur during the production process?

What is the probability of these contaminations occurring?

What are the possible consequences of these contaminations?

Identifying Critical Control Points

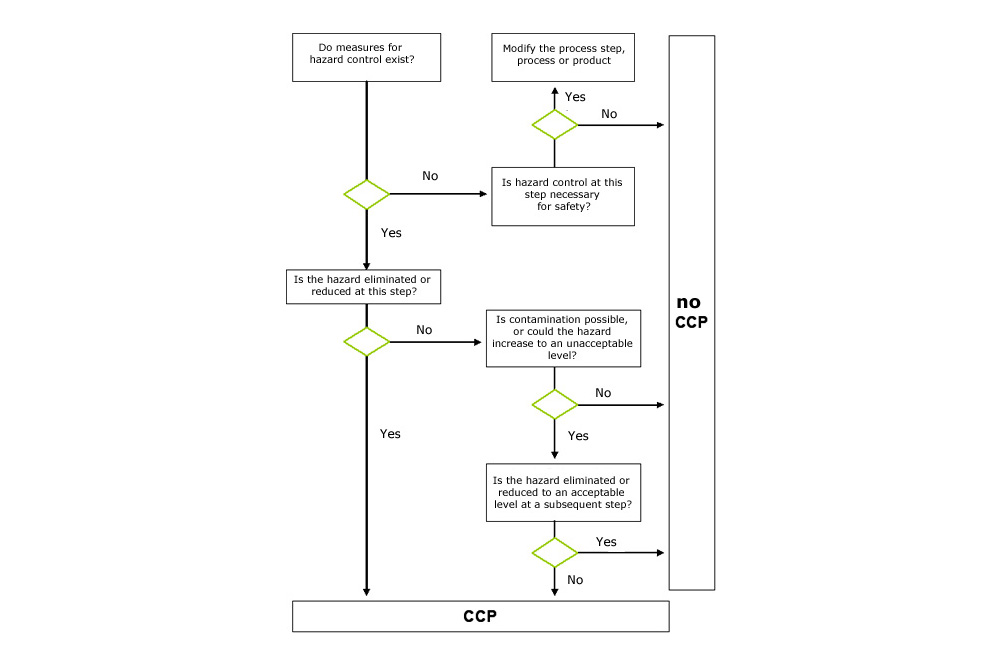

Using a decision tree has proven to be a useful aid in identifying Critical Control Points:

Inspection systems, such as metal detectors or X-ray scanners that detect and signal or automatically separate contaminants can be used at identified CCPs.

Critical Limits

Once the Critical Control Points have been identified, specific limits are defined for each of these control points. Food safety is only assured if these limits are met. For the use of metal detectors or X-ray scanners, these limits refer specifically to the scanning sensitivity, i.e. the size of the detectable contaminant, and the corresponding signalling or ejecting devices.

Establish a monitoring system

Systems to monitor whether the defined limits are met and to indicate the potential for loss of control are established for each Critical Control Point. For metal detectors and X-ray systems, this is done by using test samples to periodically check the proper functioning of the equipment.

Implement corrective actions

If the Critical Control Point limits are not met, the previously determined corrective actions must be taken.