History of Machine Vision: Factory Automation (FA)

Automation has become an inevitable trend to achieve low cost and high quality in manufacturing. From simple tasks to assembly and inspection processes that require advanced techniques, this work is being rapidly automated and productivity has increased to a higher level than before. In this article, we will briefly introduce automation and the role of image processing.

The starting point and turning point of automation

To provide the necessary value and service without the need for labor ... The history of automation challenges stretches back to ancient times. For example, it is said that there was a vending machine selling holy water in ancient Egypt. However, at that time, it probably only attracted attention as a novelty and may not have been used much in practice.

The turning point of automation came when humanity made great strides in automation during the industrial revolution, starting the era of mass production and mass consumption. A large amount of manual labor was replaced by machines and these machines began to be actively applied to promote efficiency with less errors in work and save labor. These machines also freed people from harsh working environments and from heavy, repetitive labor and they began to be used in many fields as a way to increase safety and comfort.

Automation All-Star Factory Automation

A typical example of automation in the manufacturing fields is factory automation systems. Production process automation systems do not simply take over the work from humans and assign it to machines. They play an important role as management systems to increase productivity, reduce costs and improve quality, which is why they have become indispensable.

The utility of factory automation equipment including sensors in machine tools and industrial robots is now spreading to highly difficult areas “beyond human capabilities”, one of which is image processing technology. Image processing is the manipulation and analysis of information contained in images for specific purposes. Humans obtain most of the information through their eyes and ears, but in particular, a characteristic of image information obtained through the eyes is that the amount of information to convey something understandable is very large.

However, human information communication methods have a long history. For non-speech image information, the analog era including images (still images) and text continues. Passing the era of analog images, such as murals and writing, the 20th century became the era of digital images with the advancement of electronic devices.

The Five Senses of Humans and Machines

.png)

Practical Use of Digital Image Processing

Images to Convey Various Types of Information with Greater Accuracy Than Speech ... Image technology in factory automation systems that process and effectively use digital images by computers began to be put into practical use in Japanese industry in the 1960s. This began in scientific research fields including images from artificial satellites. In the 1970s, X-ray and ultrasound imaging tests were applied in medical fields, and industrial fields as well as industrial production and distribution. Image technology was actively used to automate, improve efficiency and save labor, contributing greatly to the enhancement of quality management.

In the 1980s onwards, recognition processing techniques for drawings and document images began to improve significantly. Until then, mainframe computers were necessary, but general-purpose image processing equipment and low-cost image processing programs for processing images on personal computers became widespread, and practical use of now familiar image processing techniques began to develop. High-resolution monochrome and color images are now commonplace, and the usability of these systems will continue to increase as miniaturization, speed improvements, and cost reductions improve.

Evolving Processing Systems

.png)

Advances in Information Volume and Fast Processing

In general, 1 second of video contains 30 still image frames. In other words, with a simple calculation, the information volume increases by 30 times, and color video increases by three times, for 90 times the information volume compared to a monochrome image. Images consist of a group of small pixels divided horizontally and vertically. If you increase the number of pixels by dividing them into an even finer group, the resolution of the image increases and it becomes more precise, but the information volume also increases by that amount.

There used to be a dilemma that the more advanced the image, the more information volume increases and the processing speed becomes slower. But in recent years, the speed of image processing has continued to increase. So why can we process large amounts of information so quickly? The answer is that high-speed, high-resolution imaging elements (devices that convert images to electronic information) have emerged and high-speed integrated circuits have been developed to process large volumes of information at high speeds. There are also benefits in the practical use of high-resolution displays, from CRTs to thin-film liquid crystal displays and OLEDs, and in significantly increasing the performance of personal computers.

Changing image processing times

.png)

Optimized Factory Automation System for the “Image Age”

A system that possesses powerful information processing and imaging capabilities has not existed until now... In today's era, when we are equipped with techniques and environments for image processing that were difficult even for supercomputers half a century ago, we can certainly say that this is the “Image Age” where information can be communicated and shared visually “anywhere, with anyone, and at any time”.

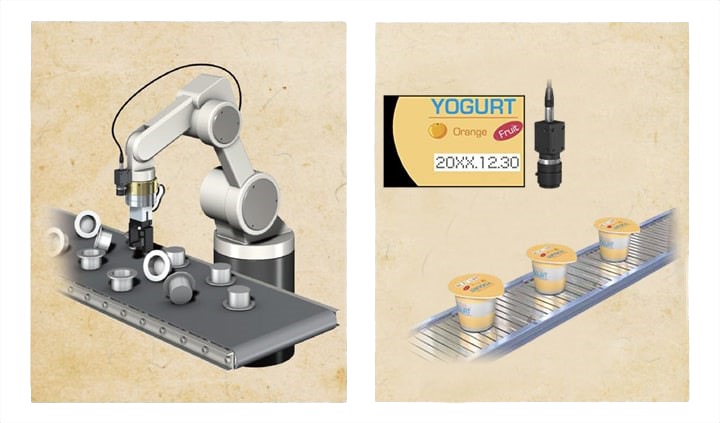

Automatic reading of printed expiration dates, product shape (outer appearance, damage, surface shape), robot-linked sorting and assembly, remote sensing including agricultural/marine product processing and sorting, etc. Image processing in factory automation systems, which continues to be applied to and put into practical use in many industrial fields, continues to develop steadily while it is being optimized according to different applications and needs.

Image processing achieves optimization of factory automation

Factory Automation - Spreading Worldwide

Image processing techniques in factory automation systems are spreading their appeal worldwide. In addition to companies from leading industrialized countries moving production functions overseas, factory automation is being rapidly adopted in newly advanced economies (such as BRIC), not only in production but also for optimization purposes. Optimizing local resources including services, maintenance and storage is becoming a driving force in expanding demand.

Manufacturing companies are now facing an era of disruption and competition on a global scale. Factory automation, which has supported production in many ways in fields including automobiles, industrial equipment, electronics, food and pharmaceuticals, has contributed to reducing size and weight, increasing efficiency and improving quality in manufacturing industries worldwide. In the future, we anticipate new usefulness with next-generation factory automation systems and increased international competitiveness by opening up the factory automation process by unifying the specifications for factory automation equipment and control software, creating effective links with ERP (1) and MES (2).

(1). Enterprise Resource Planning. An information system package to support the core business operations of companies including inventory and production status.

(2). Production Execution System. Plays the role of understanding equipment, quantities and status of raw materials and work-in-process items in real time, assembling work schedules based on production plans, issuing instructions to workers and providing information related to work processes.