Check X-rays in the Food Industry

Why are X-ray systems used to detect contaminants in food?

Product inspection has become an indispensable element in the food production process, being an absolute prerequisite for obtaining IFS certification. Contamination of food in any form can have serious consequences for the company, because under product liability law, every food manufacturer is responsible for the contamination of its products in case the consumer is harmed by such contamination. Contaminant inspection systems are used to prevent such problems. Metal detectors are most useful for detecting magnetic and non-magnetic metals but they also have their own limitations, for example in the inspection of aluminium-coated packaging materials.

The contamination of glass, ceramics, stone and similar materials in food is also a serious problem. Therefore, food X-ray detection systems are used for such applications.

How does an X-ray system work?

The X-rays for “imaging” are produced by an electric X-ray tube. A path detector that measures the incident radiation is placed above the conveyor belt. X-rays have very high energy and are therefore able to penetrate solid objects. Depending on the density of the object being inspected, the X-rays passing through the product will be attenuated to a higher (high density) or lower (low density) degree. The detector converts the remaining radiation into an electrical signal and thus the difference in density of the object being inspected can be shown in the image. The higher the density of the material, the darker its appearance on the X-ray image and vice versa. The image processing software detects the difference in contrast in the image,

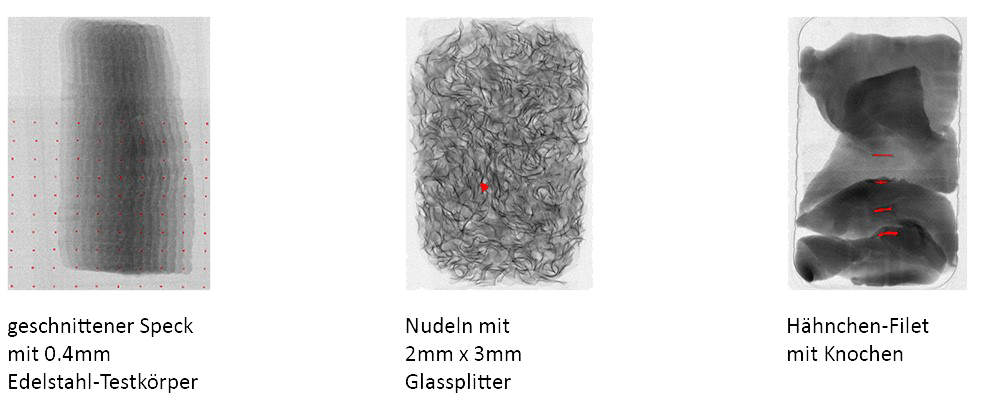

Some examples of X-rays of inspected food products:

What types of contaminants can be detected in food using X-ray systems?

Basically, X-ray systems can detect any contaminants whose basic density is different from that of the product being inspected. This typically applies to metals such as steel and stainless steel, but also to glass, sandstone, quartz, shale, and many others. Another special feature of X-ray systems is that in addition to detecting impurities, they can also detect other product defects. Missing products in packaging, unwanted air bubbles, excess or underweight, damaged products, shape deviations, and even incorrect positioning of individual components can be detected to some extent. This not only ensures product purity, but also further improves the quality of the final product.

The system is widely used in: confectionery and cereals, meat and sausages, milk, canned food, cakes, baby food, etc.

However, even X-ray technology cannot detect all types of contaminants. For example, it cannot detect thin foil, insects or mollusks, hair, wood, fibers, fabrics and plastics containing only hydrocarbons (PP, PA, PC, ...).

Are X-rays dangerous to food products or to operators?

X-rays are classified as ionizing radiation, which, if used improperly, can be dangerous to humans and the surrounding environment. However, the potential risk depends on the energy and dose of radiation. Since food production and processing is of course a very sensitive sector, the European Union has adopted a specific directive 1999/2+3EG concerning the use of X-ray-based inspection systems to ensure 100 % safety of the products being inspected:

"Food may be inspected by X-rays if the absorbed dose [...] with a maximum radiation energy of 10 MeV does not exceed 0.5 Gy."

The maximum permissible X-ray voltage for food inspection is 10 MeV (mega electron volt) = 10,000 keV (kilo electron volt)

With additional safety aspects, it is also necessary to ensure the absolutely safe use of the X-ray system in the inspection of products in the food sector:

- Only soft, low-energy X-rays are used

- The X-ray voltage and current are individually adjusted for each product

- The X-ray tube is completely shielded

- All radiation shielding is monitored by safety switches

- The X-ray can only be switched on if the system is operating perfectly

For X-ray system operators, it is also important that the maximum permissible X-ray radiation outside the system is 0.5 μSv/h.