Check the PCB image using aVisPro.

Ngày: 09/11/2020

.png)

aVisPro - PCB Image Inspection

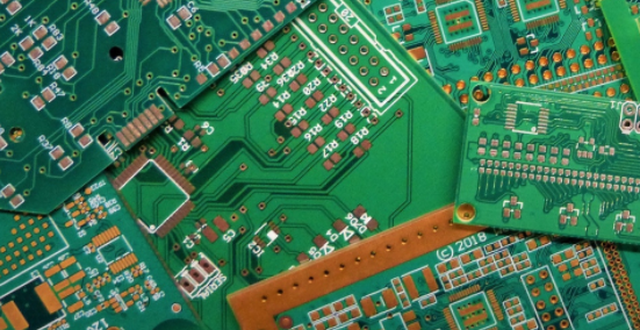

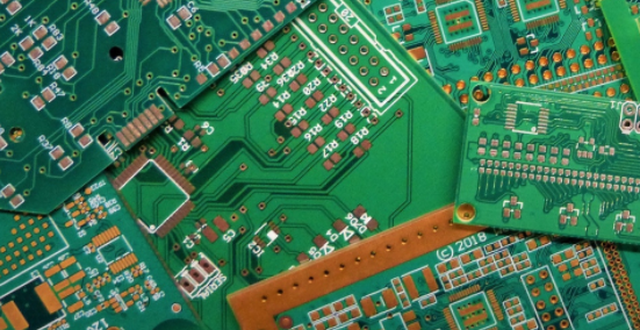

Along with the increasingly convenient and modern life and the strong development of the electronics industry, the image of PCB printed circuit boards has certainly become very familiar. We can see PCBs in many electronic devices such as: TVs, mobile phones, digital cameras, computer parts such as: Graphics cards, Motherboards... It is also used in many fields such as: Medical equipment, industrial machinery, automotive industry, lighting...

PCB (short for Printed Circuit Board) is a multi-layer and non-conductive printed circuit board, in which all electronic components are connected together on the circuit board and have a support base below. When there was no PCB, the components were connected together by wires, which increased the complexity and reliability, so it was impossible to create a large circuit like a motherboard. In PCB, all components are connected wirelessly and are connected internally, so it will reduce the complexity of the overall circuit design. PCB is used to provide power and connection between components. PCB can be customized to any specifications according to user requirements.

PCB electronic circuit board

PCBs are widely used in all fields for control, allowing simple or complex automatic operations. Therefore, PCBs are widely produced in large quantities.

For each PCB manufacturer, to ensure that the PCB operates as programmed, the installation or fabrication of the PCB must be automated and have accurate data. So if there is any error on the PCB, such as pad error, excess copper, excess glue, reverse capacitor installation, incorrect resistor value, too thick coating, IC pin overlap, etc., it can lead to incorrect calculations and operation of the board. If this board is installed on an electronic device, it will cause damage to the electronic device, causing economic losses for the manufacturer after each warranty period.

.png)