ALL IN ONE - ALL-IN-ONE SOLUTION

The Next Generation in On-Line Food Quality Control

In food production, there will no longer be a need for a single machine for each type of quality control. In fact, with new hardware and software designs being developed, it will be possible to integrate multiple inspections and technologies into a single machine.

What does all-in-one mean?

A single machine in the line integrates advanced quality control technologies, such as laser spectroscopy, hyperspectral, vision technology, weighing and X-ray, to ensure product quality and safety requirements arising from the requirements of many different machines from stakeholders in the agri-food supply chain.

Why can we consider it a milestone in the food industry?

This is a new paradigm that revolutionizes the food industry inspection market and focuses on ensuring product quality control starting from its specific features to prevent economically damaging recalls. This leads to the development of All-in-One solutions specifically for the food market.

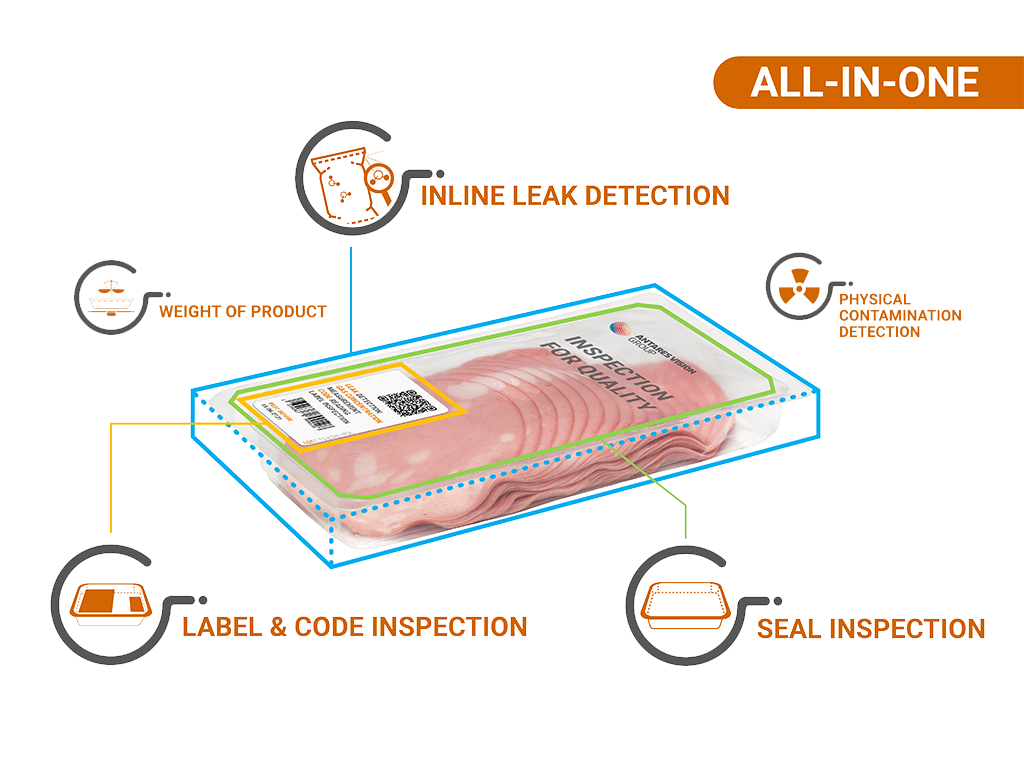

All-in-One solutions can integrate into a single machine all the necessary tests to ensure compliance with regulations, container integrity, verify any leaks, contaminants, weight, labels and information, such as expiration dates, batch codes, etc.

It is possible to put several advanced tests and technologies for quality control into a single machine. There will no longer be a need for multiple machines for multiple inspections.

What can all-in-one solutions include?

All basic tests required by the regulation are capable of:

- Detection of micro-pores in packaging: An innovative line system for detecting micro-pores can be used on trays and packages without changing the line speed or the composition of the gas that preserves the product. Based on infrared spectroscopy or gas sensors, it selectively, quickly and accurately determines the presence of target molecules leaking from the package, indicating the presence of micro-pores. As a target molecule, CO2 can be used for all products packaged in MAP, alcohol for the bakery and baking industry as well as flavorings for some specific products.

- Detection of foreign objects: such as pieces of glass, bones, metals, plastics or stones - accidentally introduced into the product during production or coming from raw materials are detected through the application of X-rays.

- Product weight checking: Fundamental to avoid food waste, monitor and optimize the efficiency of the production line and comply with regulations.

- Seal checking: The presence of food in the seal, on both transparent and colored packaging and packaging can be determined through hyperspectral technology.

- Label and code checking: This avoids sending products to the market with incorrect labels or codes (expiry date, batch code, …) or other information.

Other features:

Smaller footprint (similar in size to a checkweigher), a single user interface allows to check what is happening for a single check. Eliminating discrepancies and automating recipes in production are additional direct benefits of All-in-One solutions. They offer lower energy consumption, with significant sustainability impacts.

All-in-One solutions are also connected to digital platforms to optimize production line efficiency and supply chain transparency for product traceability along the supply chain through serialization.

All-in-One solutions revolutionize the concept of direct quality control in the food sector, as they offer the ability to include all necessary quality checks in a single machine to meet the safety and quality requirements of various stakeholders, from large-scale distribution to consumers. All-in-One solutions are designed to connect to digital data management platforms to optimize production lines and traceability along the supply chain. Companies will only have to think about what checks are needed to ensure quality and safety for consumers, and no longer have to worry about how many machines to insert into the line because one machine will be enough.