AI - Automatic monitoring and intelligent control of blow molding process

Ambient temperature, air humidity, preform weight or recycling percentage, etc., if these environmental parameters change, the blow molding process must also be readjusted or even reset. But instead of using an operator, this job is now taken over by the intelligent control system Contiloop AI – precise, fast and fully automated thanks to artificial intelligence.

- Combining hardware and software: intelligent process control based on artificial intelligence (AI)

- In daily operations: Contiloop AI measures the most important parameters of the container as well as inline environmental parameters and readjusts the blow molding process if necessary.

- If a major change is planned: the system is retrained via the IIoT platform and thus learns to adjust the blow molding process precisely for perfect bottle quality under the new conditions.

Current challenges for PET bottle production

On materials:

The unchanging trend towards lightweight bottles and the requirement to use up to 100% rPET

- Fewer materials and fluctuating material properties place greater demands on process guidance

On the blow molding machine:

Continuously increasing production per blow molding station: from 2,000 bottles/hour in 2000 to 2,750 bottles/hour today

- The smallest deviations in the bottle production process have a big impact on the production results very quickly.

On production:

Operators can work with multiple machines and systems at the same time

- There is less time for manual process guidance and inspection.

Solution: Contiloop AI

The combination of AI-based software and newly developed hardware makes it possible to automatically adjust key blow molding parameters when even the smallest deviations are detected - and thus maintain the best possible bottle quality.

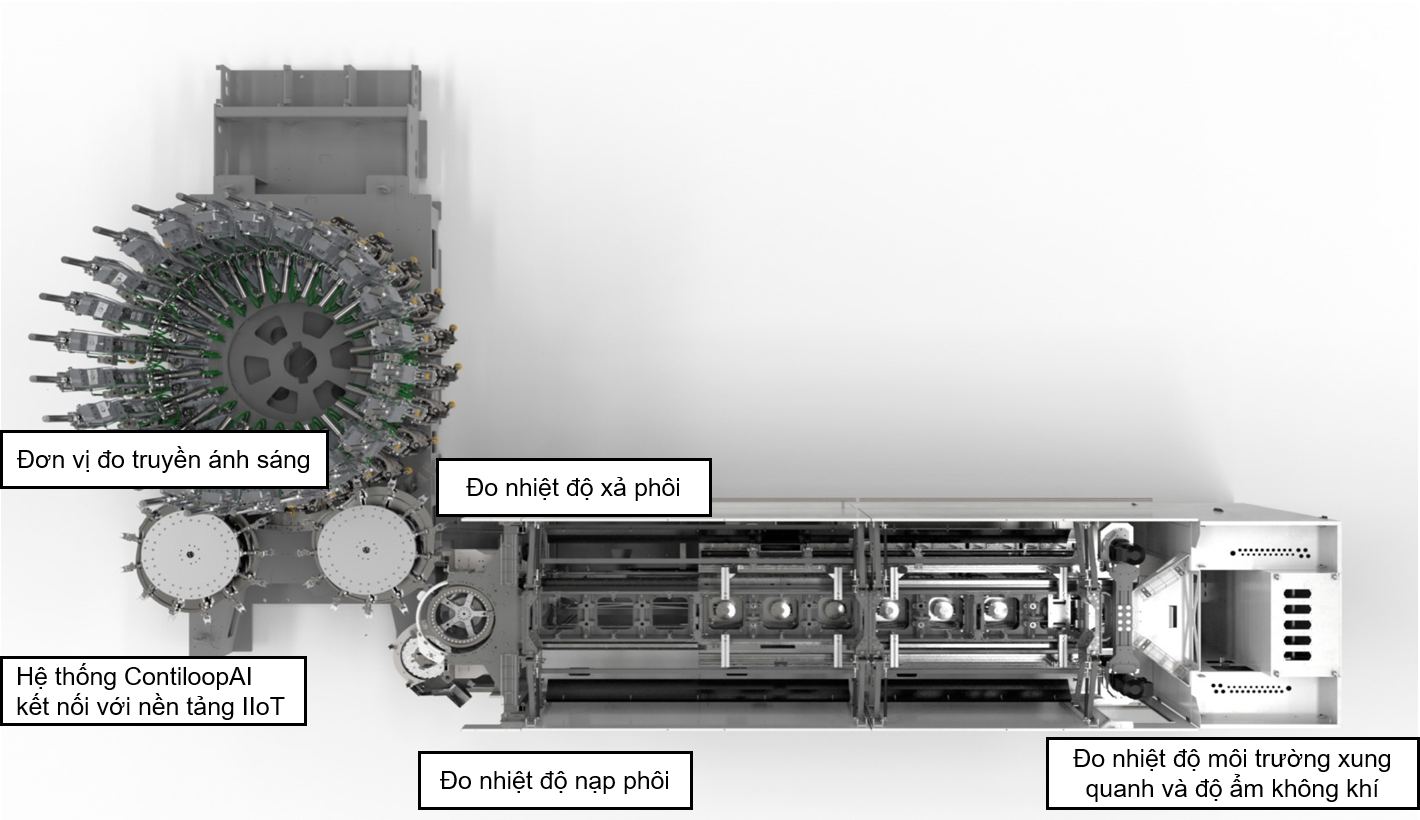

Contiloop AI at a glance

- During the discharge cycle of the blow molding machine, the light transmittance value of each container is measured at up to 32 positions.

- Additional sensor values provide additional information during the production process, such as:

-Ambient temperature

-Ambient air humidity

-Preform filling and discharging temperature

- The control system operates on a separate device and compensates for production disturbances fully automatically.

- The measurement and control data are used for further optimization and transmitted to the IIoT platform for quality assurance reasons.

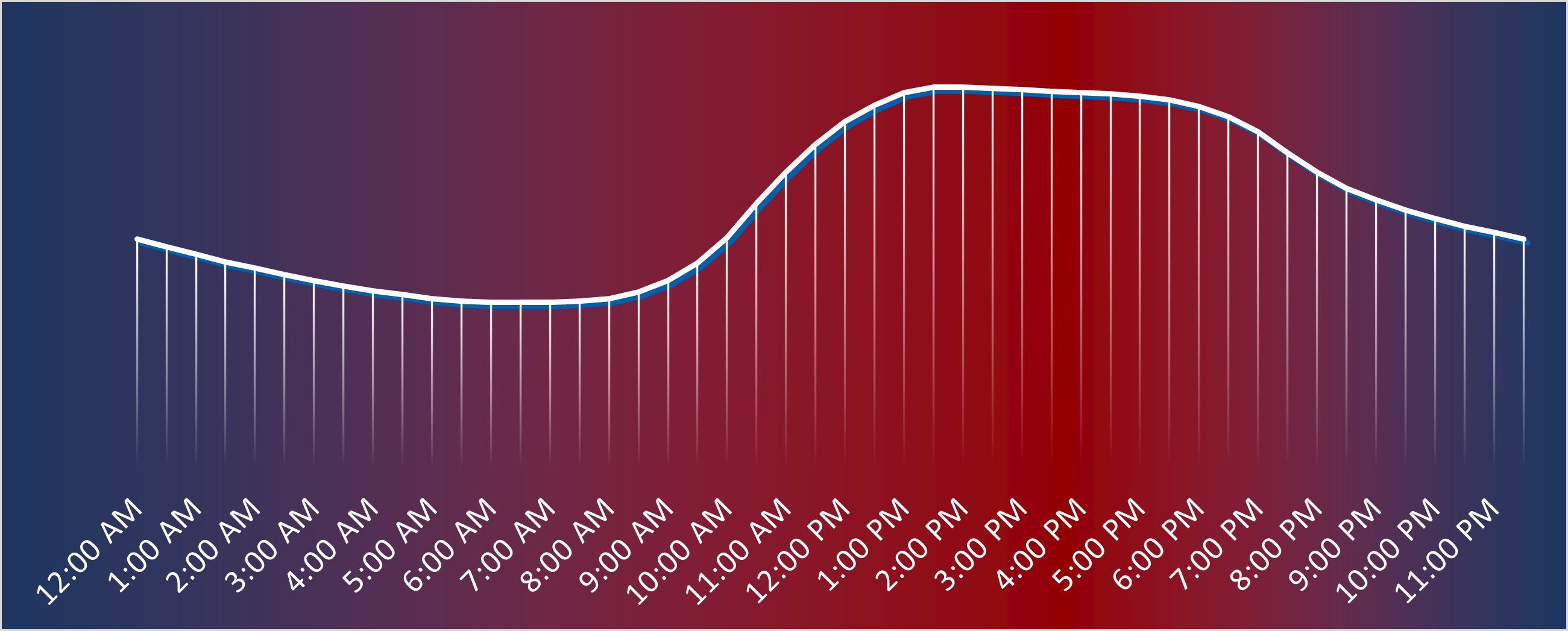

If the temperature in the production room changes throughout the day, it is usually necessary to adjust the process parameters on the blow molding machine. This task is currently performed entirely automatically by Contiloop AI.

Contiloop AI – in the production process

Details

1. Measuring unit, measuring the light transmittance value of blown PET bottles during production.

2. This transmittance value information is continuously transmitted to Contiloop AI.

3. The information is processed by agents in real time. If necessary, the process parameters are automatically adjusted.

4. The adjustments are displayed on the machine HMI.

5. The measured and processed data is transmitted to Service Contiloop AI on the IIoT platform.

6. Information related to control interventions is displayed in Service Contiloop AI.

Benefits

Less operator intervention

Contiloop AI reacts to changing environmental parameters and automatically readjusts the blow moulding process. As a result, different process configurations (e.g. day/night shifts) do not need to be adjusted, meaning that manual work can be avoided.

Independent of operator know-how and experience

The risk of the operator making incorrect process adjustments is reduced thanks to the ability to bypass manual interventions to the maximum extent. Blow moulding machines with Contiloop AI can therefore also be operated by people without any special process know-how. Personnel costs can also be reduced depending on the route.

Highest bottle quality

Very high, consistent bottle quality is achieved and the scrap rate is significantly reduced thanks to 100% light transmittance measurement and automatic process control using artificial intelligence. Therefore, random inspections will suffice where necessary.

Lightweight bottles and rPET can be produced

Mostly when using rPET, the available process window is very small. The Contiloop AI stays precisely within this narrow window and thus ensures that the quality of the container is not negatively affected by incorrect manual interventions. The use of the Contiloop AI keeps the process variation low meaning that it is possible to operate at minimum weights without generating scrap.*

* Compared to blow molding without Contiloop AI

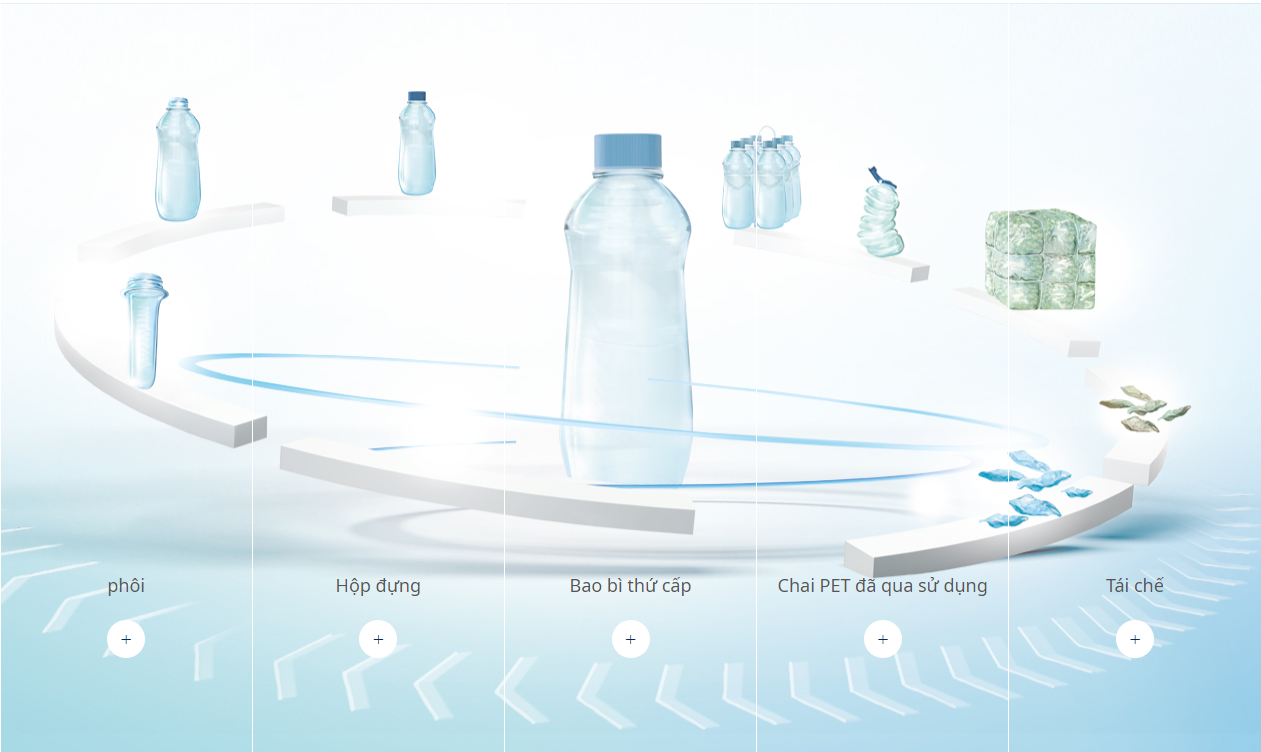

Everything you need for PET – a closed loop

Can plastic packaging be sustainable? Yes, it can be, if the production process is resource-efficient and if it is kept in a closed loop. You can achieve both with Contiloop AI. Starting with material-efficient packaging design, then low-energy bottle production, up to the recovery of used plastic: Contiloop AI gives PET bottles and other packaging the opportunity to have a sustainable, environmentally friendly life cycle – not just once, but again and again.