aAOI technology checks and detects electronic circuit board errors

.png)

aAOI - aAOI technology in the field of testing and detecting errors on electronic circuit boards 4.0

In the current era of 4.0 technology, everyone must always see electronic circuit boards, they appear everywhere on technology devices, from smartphones, laptops, PCs and even electric kettles have electronic circuit boards.

Electronic circuit boards are very commonly used in all fields for control, allowing simple or complex automatic operations. Therefore, electronic circuit boards are widely produced and in large quantities.

For each electronic circuit board manufacturer, to ensure that the circuit board operates according to what the programmer has programmed, the installation or manufacturing of the circuit board needs to be automated and requires accurate data. So if the circuit board has any errors, such as pad errors, excess copper, excess glue, reverse capacitor installation, incorrect resistor value installation, too thick coating, IC pin overlap, etc., it can lead to incorrect calculations and operation of the circuit board. If this circuit board is installed on an electronic device, it will cause damage to the electronic device, causing economic losses for the manufacturer after each warranty period. To ensure that the circuit board does not have design errors before installing it into electronic devices, we need to re-check the appearance of all the details on the circuit board such as resistors with incorrect values, capacitors installed upside down, ICs with overlapping pins, inductors, diodes, defective or damaged microcircuits, etc.

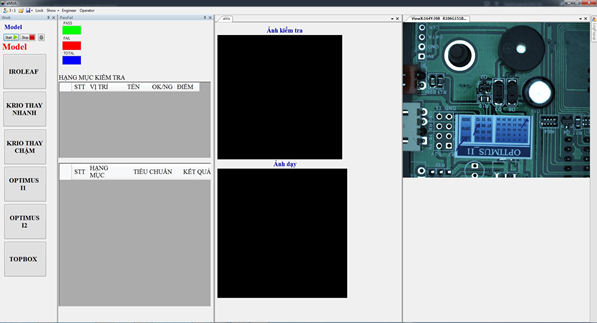

Knowing this, AVA Machine Vision Automation Co., Ltd. created aAOI technology, this technology uses a 5Mpx Industrial Camera combined with an integrated lighting system to take pictures of all the electronic components on the sample circuit board, then compare them with the circuit boards produced by the manufacturers, compare and identify each component. For each component, there will be a different comparison level and comparison value. When a component has an error, the aAOI software integrated in the computer will send back the image information of that component.

Thanks to that, the manufacturer will promptly replace, remove or repair the damaged circuit board before assembling it into the electronic device, thereby saving labor costs for checking circuit board errors and saving costs for warranty, replacement and repair of electronic devices.

Successfully applied in the inspection of appearance as well as the function of electronic circuit boards of IRO3.0 water purifier at Tecomen Group, the circuit board inspection is faster and more accurate than ever. Some images of the circuit board inspection:

Figure 1. Image of the aAOI software interface

.png)

Figure 2. Components are zoned and named separately to have different inspection items for each component type.

.png)

Figure 3. Check capacitor C13 for reversed polarity and report NG.

.png)

Figure 4. Fixture for fixing the circuit board to inspect the appearance of the IRO3.0 circuit board.

.png)

Figure 5. Jig to fix the circuit board and pneumatic coils to replace the button press operation to test the circuit board function

.png)

Figure 6. aAOI software displays the results of the board's functional test