Quality control system on the card

INTRODUCTION

Nowadays, the use of plastic cards such as ATM cards, membership cards, or even driver's licenses is becoming more and more popular, leading to an increase in the demand for card production and printing. In that context, many machines have appeared to serve the field of card production automation, however, in Vietnam, some stages, especially the stage of checking the quality of printed cards, are still mainly done manually by expensive and quite complicated machines. In response to that requirement, AVA developed a system of machines to check the quality of printed cards to improve labor productivity as well as ensure the stability of the quality of the production process.

1. Inspection requirements: printed card products include types of cards such as ATM cards, membership cards, and promotional cards. The system must be able to check all types of cards with a maximum size of 54mm x 86mm with typical errors such as color errors, errors due to dirty cards, or errors such as shadow, stripes, and roughness on the card surface.

2. Overview of the card checking system

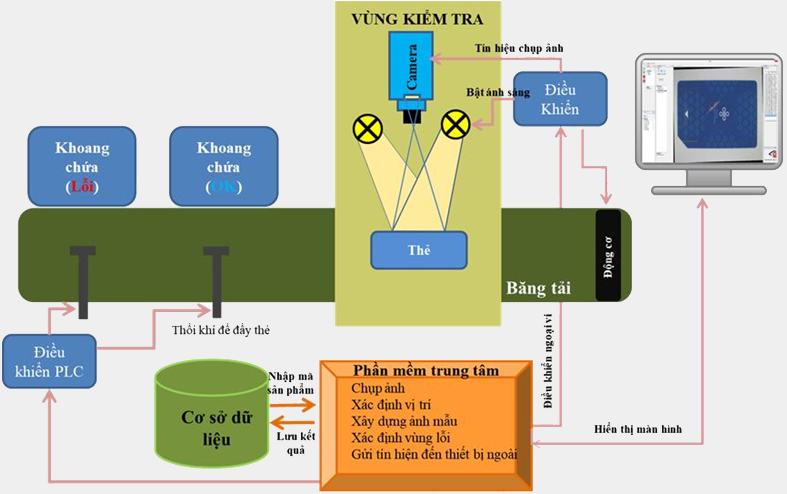

The inspection system is built according to the concept of including all components, in which the main component is the inspection block including the camera and lighting system that is responsible for taking pictures of the product. The card is fed into the conveyor belt through the input feeder, passing through the inspection and sorting system, OK products will be transported by the conveyor belt to a separate storage area and NG products will be rejected. The entire system is controlled by a central computer connected to the PLC to control the electrical equipment.

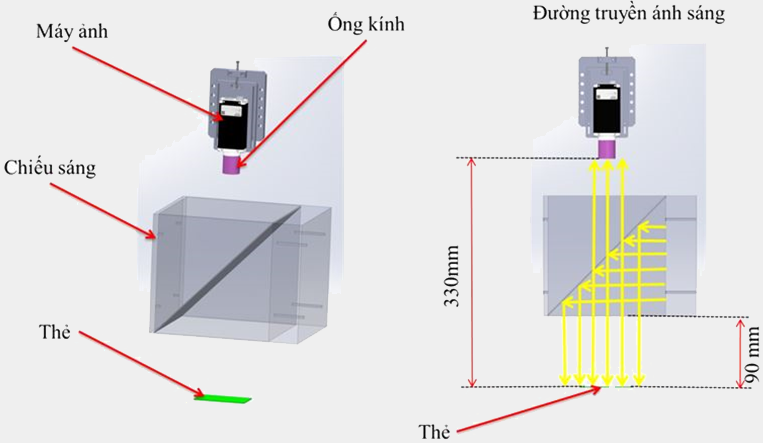

The lighting system is specially designed to highlight card errors

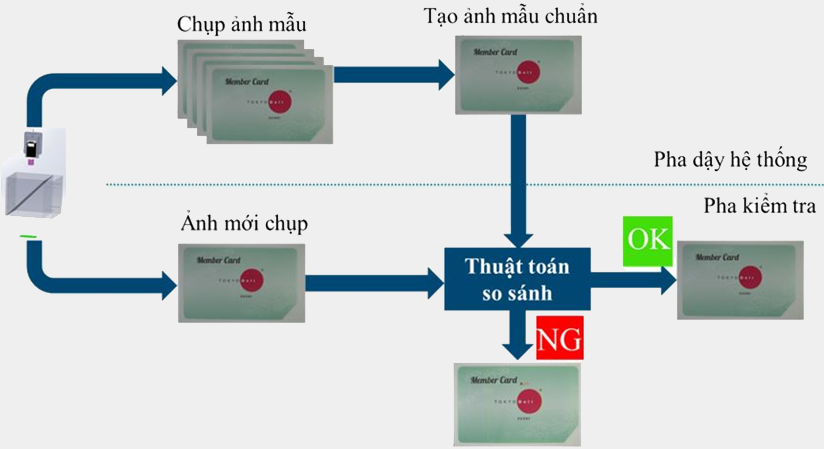

AVA software for card testing is built on very powerful algorithms that ensure product error detection.

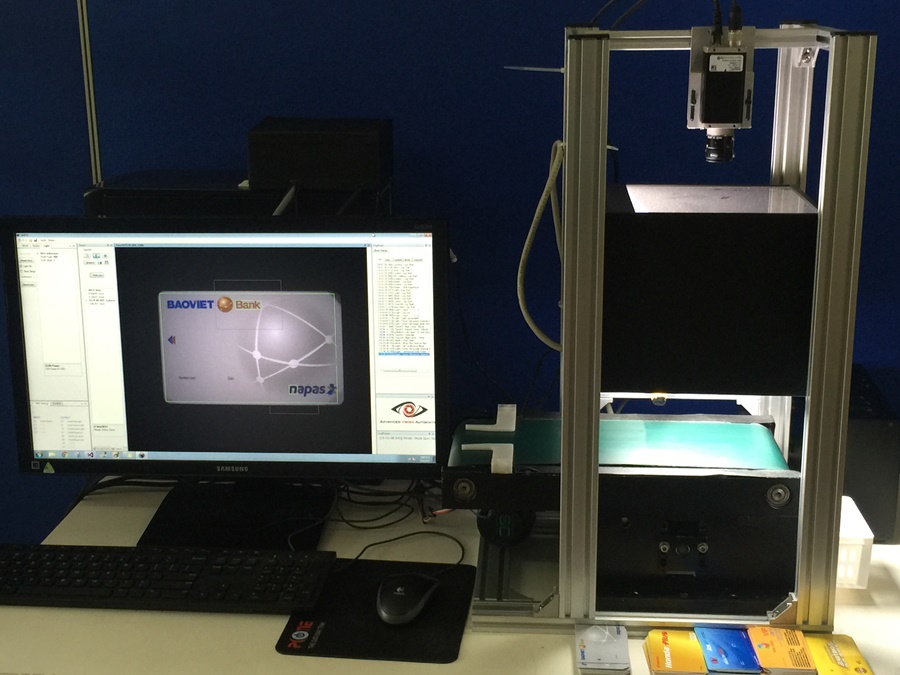

AVA's card verification system:

Video model of the inspection system: