Check the ceramic products

Ngày: 22/03/2025

INTRODUCTION

Ceramics are traditional products that have existed for a long time and are produced by hand. However, with the increasing market demand, many businesses have boldly invested in industrial ceramic production lines, which can produce thousands of products every day. Fast production, large quantities but still need to ensure quality. To solve this problem, AVA Vision provides products to check errors on the ceramic surface, the automatic system gives fast and accurate results from small errors, helps to optimize the production process, propose solutions to fix defective products in a timely manner to ensure output quality, minimize production costs, labor costs.

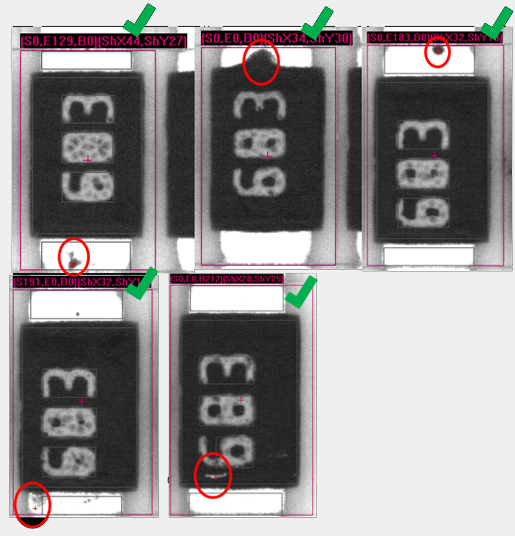

Some common errors on the surface of ceramic products: printing in the wrong position, stains, errors on the lettering area, scratches, misprints, missing parts of interest,...

.png)

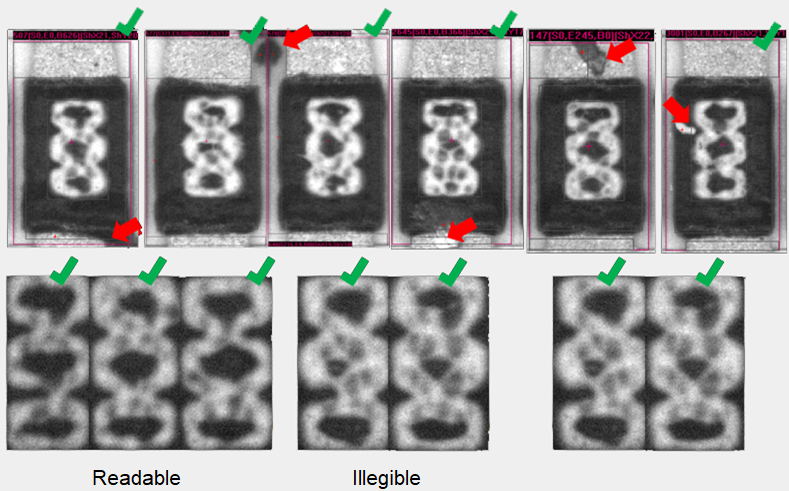

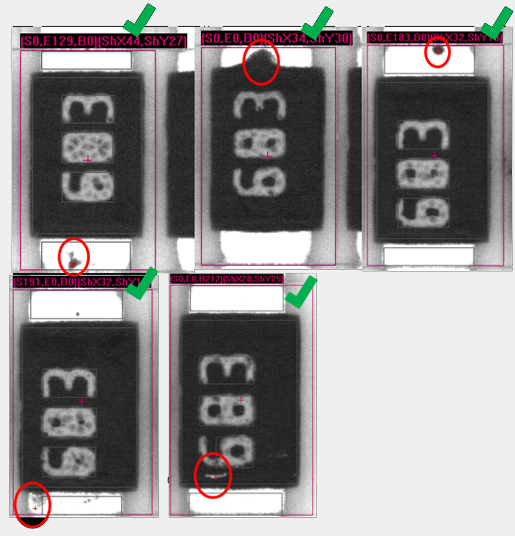

Error in the text area

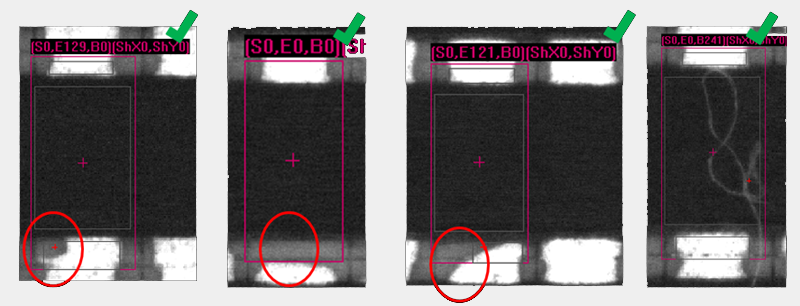

Error in position deviation

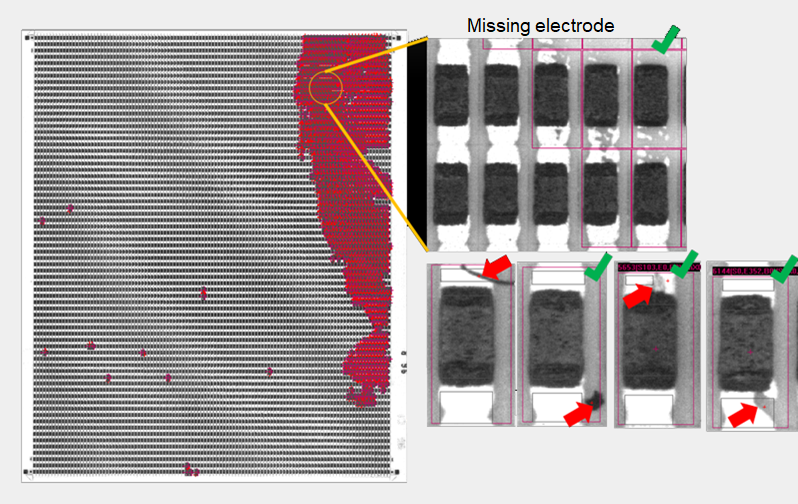

Missing errors, omissions

Errors, Contamination

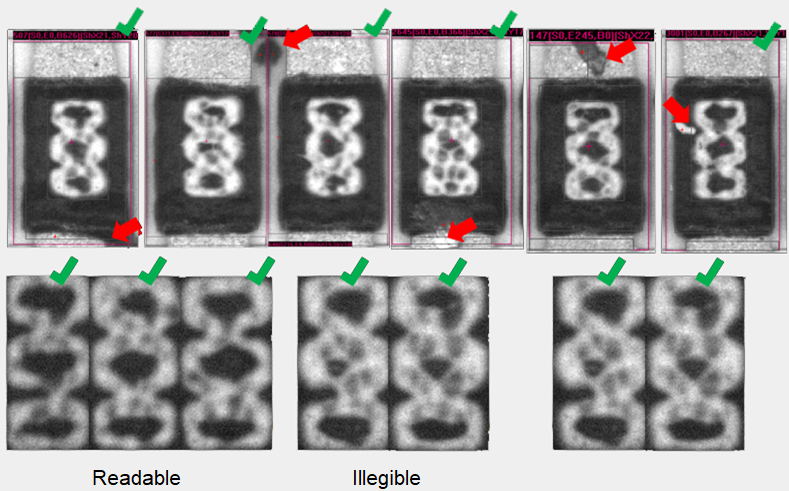

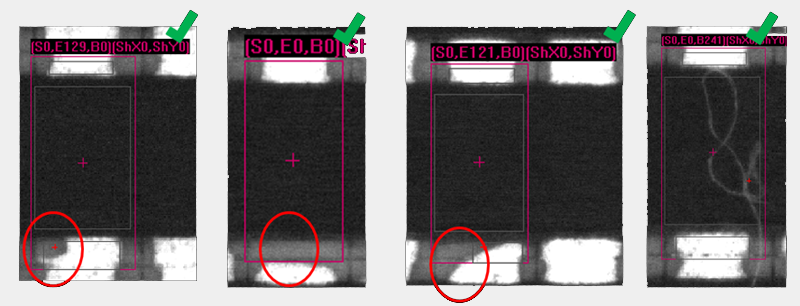

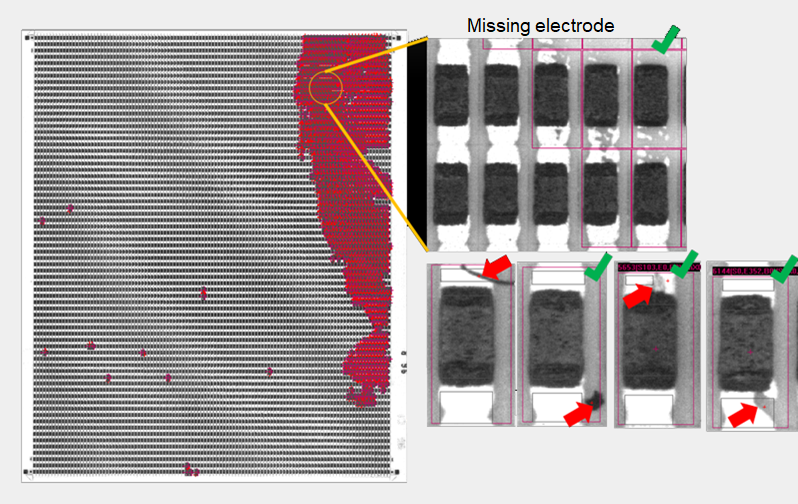

AVA Vision's software automatically locates areas of interest on the product for inspection.

.png)

Locate, test area, error area

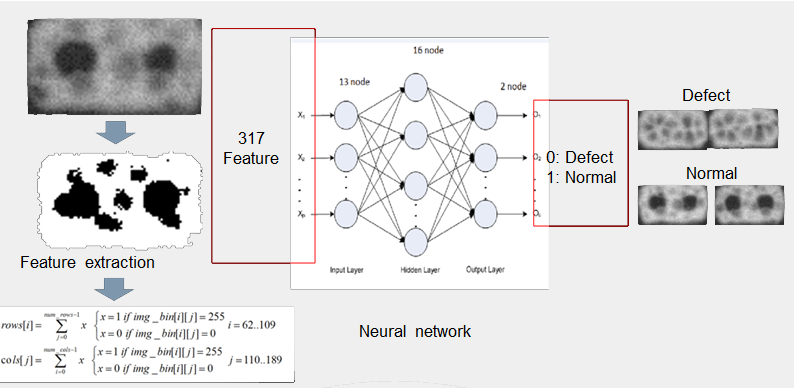

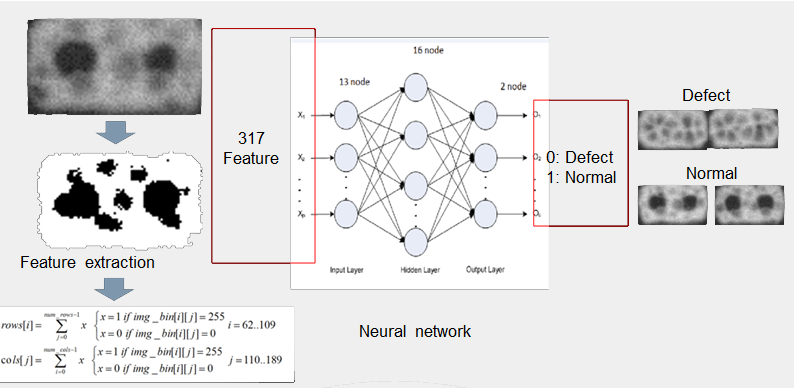

AVA Vision applies deep learning method, extracting product features, using training neural network. The advantage of the method is that it can give a lot of data to the machine without worrying about storage capacity, the more the machine learns, the more accurate the error judgment results are.

Deep Learning Applications in Ceramic Inspection

After the training process is completed, the machine conducts inspection and classification of errors, and notifies the user.

Test results

AVA Vision's automatic error detection, inspection and classification system accompanies your business to bring quality products to consumers, optimizing production in line with modern industry 4.0.

.png)

.png)