Why Are AI Cameras Changing the Game in Food Industry Quality Control?

In a modern food production line, quality is no longer just a "nice to have" factor - it has become a condition for survival. A small mistake in packaging, a burn mark on the surface, or a foreign object left behind... can all lead to major consequences: returned goods, loss of consumer trust, product recalls, or even contract bankruptcy. In this context, AI cameras (machine vision systems using artificial intelligence) are becoming the new "technological referee" - completely changing the way businesses control quality.

1. Overcome the Limits of Manual Testing

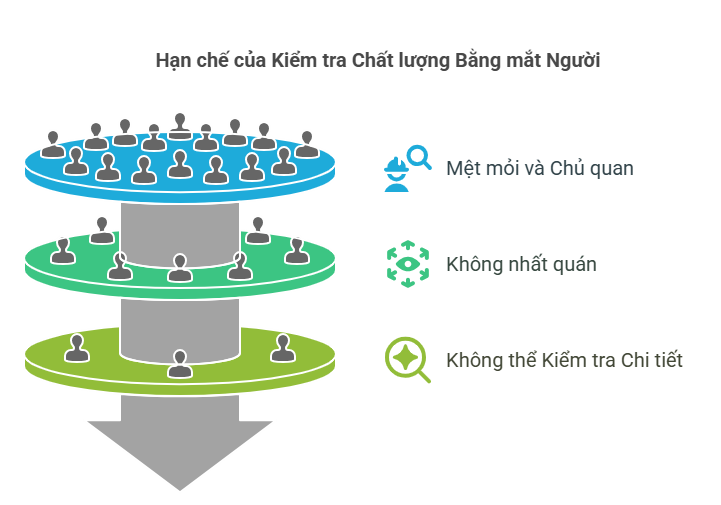

Limits of human visual inspection

For many years, human visual inspection has been the main method for quality assurance. However, this method has increasingly exposed many weaknesses:

- Fatigue and subjectivity: Workers inspect thousands of products per hour – the human eye cannot maintain absolute accuracy.

- Inconsistency: Each person has a different standard of vision, leading to errors in error assessment.

- Inability to inspect details: Super small defects, opaque foreign objects, or subtle color deviations are often missed.

For example: A small burn mark on the cake shell, or a piece of transparent plastic falling into the product – it is very difficult for the human eye to detect. But AI does not miss it.

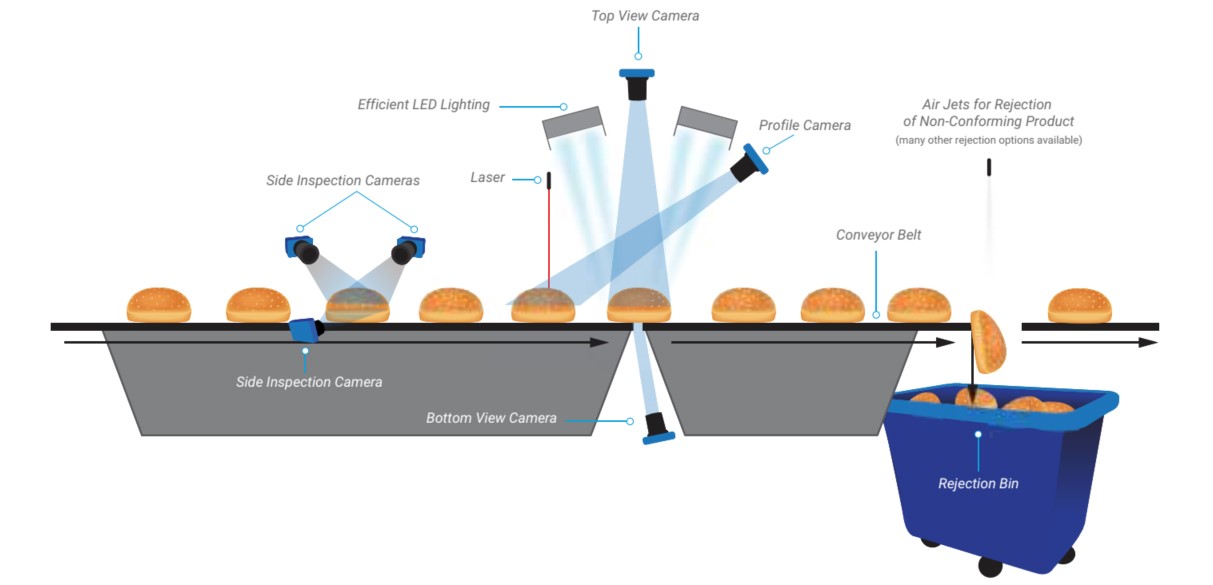

2. AI camera – a new generation of quality control tool

The AI camera inspection system provided by AVATECH integrates machine vision technology, deep learning, and real-time analysis. Highlights include:

“Seeing” Smarter Than Humans

AI doesn’t just see in pixels – it also analyses shape, texture, colour, movement and potential defects. This allows the system to detect:

- Distorted, cracked, or deformed products.

- Wrong colour or burnt spots.

- Foreign objects: plastic, wood, iron pieces, insects, air bubbles…

- Packaging errors, wrong labels, misaligned labels or wrongly closed lids.

Superior speed

The system can process hundreds of images per second. At such a speed, the AI camera inspects all products 100% inline – no product is missed, even when the line is operating continuously 24/7.

.png)

Millimeter Details

High-resolution images combined with deep learning algorithms help detect microscopic defects that are invisible to the human eye or traditional detectors.

AI camera system checks the corners of the wheel in detail

3. Combining AVATECH system – standardizing smart inspection

AVATECH not only provides AI cameras, but also integrates a complete set of smart quality inspection solutions:

- Machine Vision: Check shape, size, color and surface defects.

- Component analysis system (NIR, hyperspectral): Check input materials such as protein, moisture, impurities.

- Smart statistics & warning software: Analyze error trends, evaluate performance of each line, early warning.

.png)

A comprehensive shaft inspection system from AVATECH

Strengths: The entire system can communicate two-way with ERP or MES systems, helping to synchronize production data – quality – reporting – traceability.

4. Quick comparison: AI vs. Manual inspection

|

Criteria |

Manual Inspection |

AI Camera + AVATECH |

|

Speed |

5–10 products/min |

>300 products/min |

|

Consistency |

Variable by person |

100% stable |

|

Accuracy |

85–90% |

>99.5% |

|

Micro-defects |

Often missed |

Detectable |

|

Data storage |

None / manual |

Automatic, full |

|

Production optimization |

No |

Trend analysis available |

5. Proactive Control – The Key to Risk Reduction

It's time for food factories to move from a "post-inspection" mindset to a "pre-prevention" mindset. Don't wait until the goods are returned to review the quality - it's too late.

AI cameras are the first line of defense:

- Help prevent errors right in the chain.

- Reduce losses due to defective products.

- Increase trust from customers, supermarkets, distributors.

Conclusion: AI does not replace humans - AI helps humans control better

AI cameras are not intended to replace workers, but to become the "super eyes" of the production line, helping people focus on processing and improving. With AVATECH, businesses not only own technology - but also own a comprehensive quality control ecosystem, standardized according to international standards.

Are you producing food with high requirements for quality and safety?

Let AVATECH advise on the right AI camera system - invest once, save the whole process.