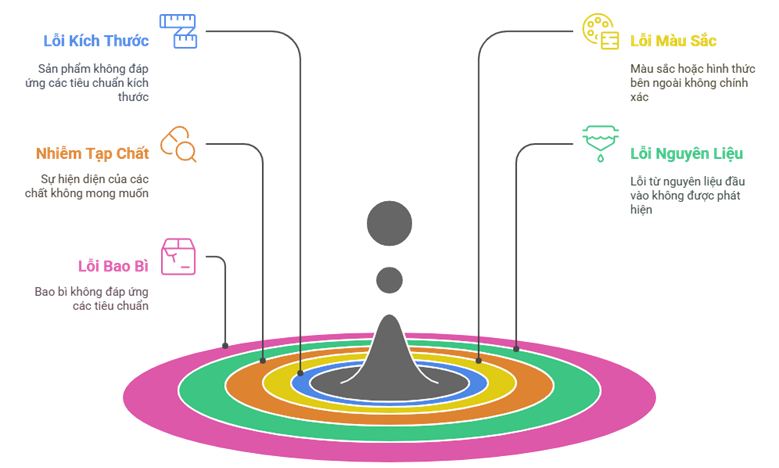

Preventing Defects Before Packing – 5 Common Risks

In modern manufacturing, errors are not only a technical risk but also a high price – from financial losses, loss of brand reputation to the risk of mass recalls. One of the common reasons for product returns is due to errors not being detected in time before packaging. But thanks to the intelligent inspection system using machine vision (AI Vision), businesses can completely control quality right from the beginning of the chain, avoiding risks right from within the production line.

AVATECH introduces the 5 most common types of errors – and how image inspection technology helps “stop” problems before the goods reach customers.

5 common product defects

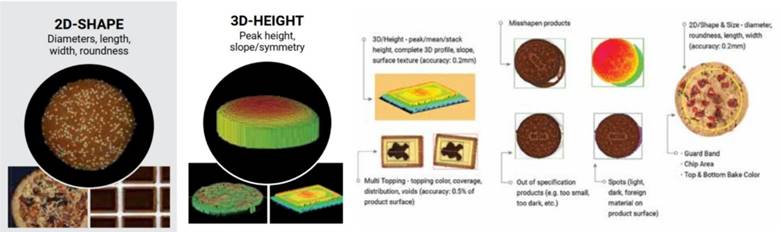

1. Products that do not meet shape - size - volume standards

Defects such as deformation, uneven size, incorrect weight or distorted shape are the leading causes of customer rejection of products.

The visual inspection system can:

- Compare product geometry frame by frame in real time.

- Check every millimeter of size, volume and shape to detect products that are too small, too large or asymmetrical.

- Eliminate non-conforming products right on the line, reducing the rate of defective products that escape in just a few milliseconds.

Check the shape and size of the cake

Benefits: Maintain quality standards, avoid losing trust from distributors or end consumers.

2. Color and appearance errors

Color is the first impression factor – but it is also the most easily distorted factor.

Common errors:

- Color is too dark or too light, black spots, burnt spots.

- Mottled surface, dirt, grit.

- For noodles: gray spots, discoloration, poor brightness.

AVATECH's solution:

Industrial cameras combined with deep learning AI algorithms can accurately analyze each color area, thereby identifying even the smallest color deviations, even in products moving at high speed.

Avoidable consequences: Avoid the phenomenon of customers "doubting the quality", returning the goods with the reason "it doesn't look as good as the sample", thereby reducing the risk of mass returns.

.png)

Standard baking color

3. Contamination and foreign materials

Just a small piece of plastic, wood or rubber left behind is enough to cause a large-scale recall for a business.

Hard-to-detect materials: Transparent plastic, paper, fabric, conveyor belt debris, insects, or even metal pieces from equipment.

How does inspection technology help?

AI Vision inspection systems or combined X-rays and NIR allow for the detection of low-density materials – something that traditional metal detectors cannot do.

Impact: Avoid the risk of losing the market, litigation, and especially protect brand reputation in the consumer manufacturing industry.

Stones mixed in coffee and rice are difficult to detect.

4. Input material errors - not detected early

Input material problems that are not detected early will lead to a series of errors in texture, density, color and taste.

Common errors:

- Protein is too high/low → affects texture and elasticity.

- Damaged starch → causes stickiness, cracking, rapid degeneration.

- Incorrect moisture, ash or enzyme content.

Benefits of early inspection with imaging systems or NIR rapid analysis:

- Control raw materials as soon as they are received in the warehouse or before they are mixed.

- Early warning for the factory, helping to promptly adjust the formula or eliminate defective batches.

5. Packaging – label – lid errors do not meet requirements

A perfect quality product can still be returned… just because the lid is bent, the label is misaligned or the label is wrinkled, the barcode is missing.

Common errors:

- The lid is misaligned, pressed too much, the anti-counterfeit strip is defective.

- Label is misaligned, missing label, barcode is unreadable.

- Contamination, oil stains, scratches on the surface.

AVATECH system inspection features:

- Detect packaging errors immediately after the packaging or label printing process.

- Integrated analysis software to trace the origin of errors, identify molds, chamber numbers, and defective lines.

Check the faulty lid

From “passive correction” to “proactive prevention”

The cost of each product recall is not only measured in money. It is also:

- Loss of contracts with retailers.

- Loss of consumer trust.

- Brand damage accumulated over many years.

The intelligent inspection system is the “last line of defense” before the product leaves the factory.

AVATECH – Automation Quality Control Specialist

With experience in implementing many systems for domestic and foreign enterprises, AVATECH brings inspection solutions using machine vision, NIR, sensors and analysis software – all intelligently and flexibly integrated for each type of production line.